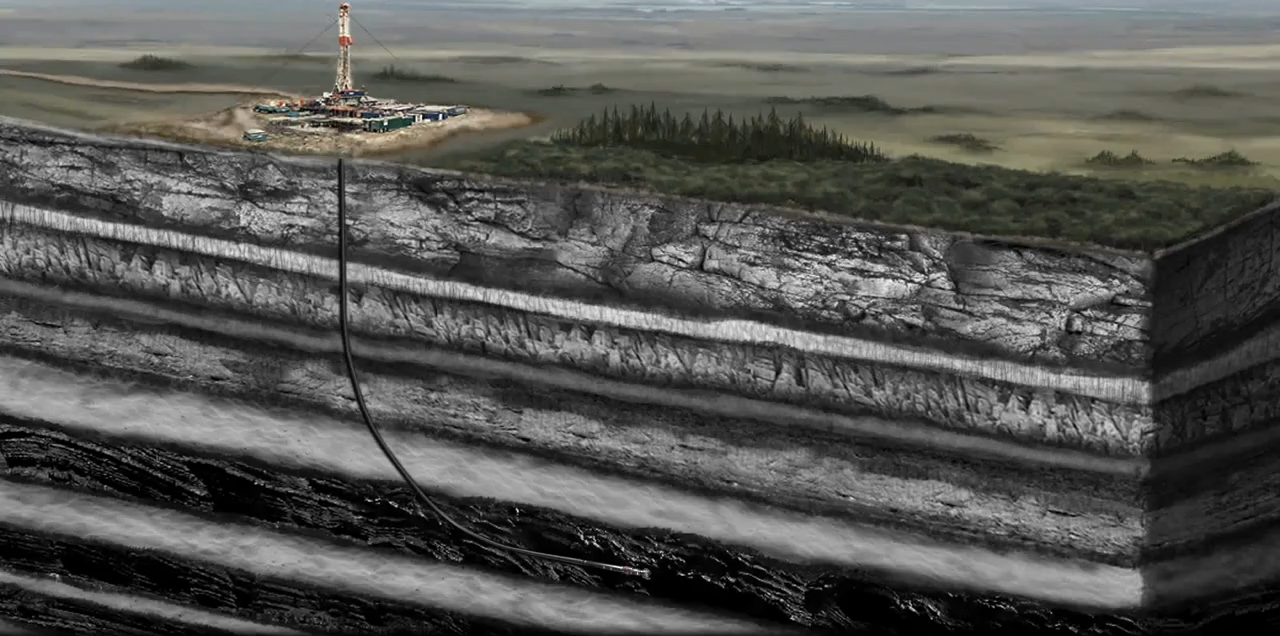

Industry Performance

Petroleum Exploration

Key parts of oil drilling machine

一、BU shaft parts

|

|

- Material for 15-15HS high strength non magnetic stainless steel or high temperature nickel based alloy Inconel 718

- Material by heat treatment, high strength, high toughness, difficult cutting processing materials, processing easy deformation, optimization processing order to offset or in the control range

- API taper thread, Spiralock self locking screw

- Special fixture machining space inclined hole, good rigidity, high reliability

- The inner face of the large and medium hole is more than one small hole, the special gun drill jig is used to ensure the position relationship between the holes.

- Three 100% coordinates (CMM) final detection

二、DCLong axis parts

- Material for 316L austenitic stainless steel or aluminum bronze alloy

- Complex structure, thin and thin wall, more than 2000 processing characteristics

- Position control of the entire range of control hole 0.3mm

- The total length of 2500mm to 4500mm, the length of the direction of the size of the heat affected significantly

- 100% Three coordinates (CMM) final detection

三、Key parts for piston pump

The main parts for oil field acidification, cementing, fracturing, sealing well and other intermittent operation with high pressure, high displacement, high power piston pump in the crankshaft, connecting rod, cross head

1)Crankshaft class

(Crankshaft photograph)

- 42CrMo Alloy structural steel

- ASME B92.1Involute spline

- Micro deformation nitriding process

2)Connecting rod

- Connecting rod photo)

- Precision casting

3)Cross head

(Cross head photo)

- Precision casting

- Wear resistant surface coating(Babbitt metal)